Safari Turbocharger Systems for 4WD diesel offroad vehicles

|

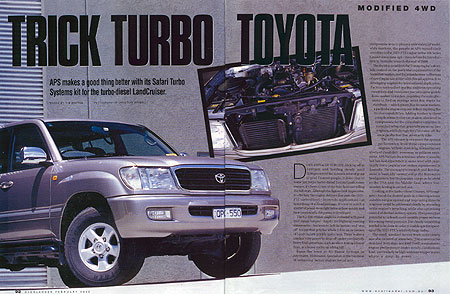

Trick Toyota Turbo

by Australia's most highly respected 4WD magazine - Overlander |

| APS makes a good thing better with its Safari Turbo Systems kit for the turbo-diesel LandCruiser. Does 430 Nm OF TORQUE, kicking off at 1400 rpm and holding steady until 3200 rpm sound like a decent serve of grunt to you? To most people, it does – but to some 100 Series turbo-diesel Toyota LandCruiser owners, it’s been a case of the bare facts not telling the full story. Although the figures look impressive, it’s the way the engine delivers that puts the 1HD-FTE turbo-diesel – in certain applications – at something of a disadvantage. It’s not so much a matter of power-to-weight ratios as how quickly and how consistently the power is developed. The 4.2-litre engine might be endowed with good mid-range torque – handy for highway passing manoeuvres – but tends to lack the bottom-end ‘step off’ torque that gets the whole 2.6 or more tones of LandCruiser quickly under way. There is also a tendency for power to drop off under consistently heavy load situations, such as when towing a horse float, or a heavy trailer up a long hill. Enter the team at APS Engineering in Croydon, Melbourne. Specialists in the business of ‘enhancing’ factory engines forced into compromise so as to please a wide variety of world-wide markets, the people at APS turned their attention to the 1HD-FTE engine in the 100 Series Cruiser some time ago – even before its introduction to Australia towards the end of 2000. The decision to address the Toyota engine’s shortfalls centred on the particular requirements of the Australian market, and the manufacturer’s dilemma of needing to use a one-size-fits-all approach to developing engines for international application. Factors such as fuel quality, ambient operating conditions and consumer use vary quite widely from market to market, requiring the manufacturer to find an average level that works for everybody – which means that for some markets, a particular engine may not deliver anything like its true capabilities. Adding further to these complications is that car-makers also need to compensate for the cumulative variables in manufacturing that generally mean no two engines, even though they’ve come off the same production line, are exactly alike The APS mission is to extract the optimal performance from these compromised engines, without stretching normal factory levels of durability, economy or exhaust emissions. APS focuses its attention where it sees fit but has had experience at some level with practically every popular car-maker represented in Australia. The company’s research and development is basically carried out at the Bayswater headquarters, but its programs can go as far afield as the USA and the Middle East, where hot weather testing is carried out. Looking at the turbo-diesel Cruiser, APS engineers found the desired goals in achieving a more useable torque spread and improving throttle response could be addressed chiefly by attending to the engine’s breathing, while also optimizing control of the fuel delivery system. The system had potential to unleash more useable power without increasing boost pressure, but clearly something needed to be done in order to enable quicker spool-up of the 1HD-FTE’s relatively large turbo. The small, standard factory intercooler clearly was also in need of attention. The conservative standard item does not lend itself to consistent engine performance under steady, continuous load, particularly in high ambient temperatures where a drop in power between ten and fifteen percent is not untypical. So APS designed a new, larger intercooler able to remove more temperature from the intake charge over consistently longer periods. A cooler intake charge equals better combustion efficiency and more power. |

to assist in getting the engine to breathe better. Top Right: The old intercooler (left) as compared to the new Safari unit (right). |

| Improving the spool-up ability of the turbo led to the exhaust. The standard system worked fine within standard, compromised factory parameters, but obviously wasn’t going to be up to the task of dealing with the extra efficiency contributed by the larger intercooler at the upstream end. From 1700 rpm, the standard system is able to produce useful power but below that, it tends to fall into a hole – partly explaining the step-off tardiness. APS found this could be noticeably improved via a better balance of backpressure and designed a new, three-inch exhaust system to give just that. Clearly these revisions to the turbo-diesel’s breathing meant that the engine management system would also need to be addressed and this is where APS looked to its expertise in optimizing standard factory systems. The company believes that accurate control of fuel and timing is central to any engine enhancement, yet is an area often overlooked by those seeking to extract more power from a modern engine. Addressing these areas is both made easier and more difficult by the widening use of electronics in engine management systems, but harnessing this potential is an area that is largely misunderstood. Central to the enhanced engine’s operation is the ‘Unichip’ – an extruded aluminium box smaller than two cigarette packets that contains the electronic circuitry to manage the enhanced engine. The Unichip steps in above idle to precisely control things such as air-fuel ratio and injection timing, while the standard management system is left to look after regular parameters as cold start and idle speed. The programmable Unichip is claimed to be more durable than many factory components and is being used around Australia by car-owners keen to extract more efficiency from their engines, merely by tapping into the compromised potential that resides within. One of the main charms of the Unichip is that it allows all the original engine management system’s functions to be retained. This means that while important functions such as fuel supply and, in the case of a petrol engine, ignition can be modified to provide optimum individualized performance. All other parameters controlled by the regular ECU operate exactly as they did before the enhancement process. As far as the Toyota is concerned, none of this represents anything radical in terms of modifications of the standard 1HD-FTE engine, but does result in demonstrable across-the-board improvements in driveability. The official figures give a torque improvement of 18 per cent, as well as a lift in power of twelve per cent but these figures tell a less than complete story. On the road, the APS-enhanced LandCruiser undergoes a subtle but forceful transformation. Left to its own devices and upshifting (in automatic versions) at 3700 rpm, the Cruiser provides a steady, seamless surge of acceleration. It feels somehow lighter on its feet, eager to surge forward even with the merest tickle of the accelerator pedal and seemingly more ready to kick down. Perhaps the most impressive aspect is that the optimized Cruiser drives as quietly and easily as a regular, off-the-shelf model. Nothing is compromised in the extraction of the extra urge. We didn’t get to drive in towing mode, but we believe the claim that the much more useable torque curve will accelerate the Cruiser off the mark quickly enough to match regular traffic, even with a fully laden tandem trailer. Of course, for heavy-duty applications the Cruiser’s manual five-speed gearbox is the recommended option, as it copes with a big load better than the automatic. APS says the enhancements also mean the 1HD-FTE engine runs more economically than in standard form – which makes sense considering the turbo and fuel delivery systems are all essentially standard items. They are merely working in a more efficient environment. Of course all this is only chipping away at the edges of what would be possible with the turbo-diesel. There’s not doubt that attention to the exhaust manifold, or further work on the turbo system, would unleash considerably more power. But there’s a point at which the edges of the engine’s reliability are being nudged. The optimized Cruiser feels more refined in many ways than the standard turbo-diesel, yet will snarl away with real gusto if asked. Importantly, that initial off-the-mark lag familiar to many 1HD-FTE drivers is no longer an issue. Because the engine is more readily producing low-rpm torque, there is a tendency to use fewer rpm during acceleration, meaning quieter, more fuel-efficient operation. APS Engineering will have the turbo-diesel conversion on the market about the time this issue goes to press and is anticipating a price of around $3,500. Installation takes one day and is carried out through a specialized network of workshops covering all major population centres throughout Australia. For any turbo-diesel owner, this is a well-considered investment that should save money at the fuel pump, while also taking the strain off any of the heavy-duty chores to which the big 4WD naturally lends itself.  Above: The Unichip module handles the engine tuning parameters. |